How will 5G technology enable collaborative robotics in industrial environments?

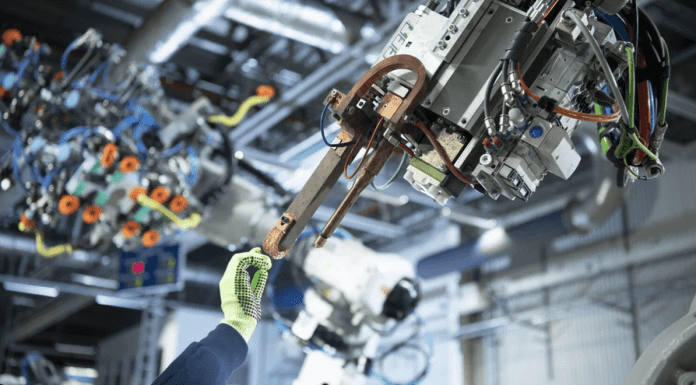

According to Singapore telco Singtel, manufacturers are using a variety of robots for industrial tasks. There are robots that can move products from one location to another and robots that are designed to work alongside humans in the warehouse. Most of these industrial robots are connected using a wired system as the data required to power a warehouse of robots cannot be supported by current wireless speeds. This is why, the implementation of 5G technology will be key for the widespread of the collaborative robotics concept.

“The emergence of 5G will make robot use in manufacturing faster and more efficient without the heft or limitation of cables. Manufacturing robots are expected to see significant growth in the next few years,” Singtel said.

The Asian telco said that a company that makes use of collaborative robotics is Ocado, a U.K.-based online grocery market. Their smart factory in Andover, England has over 1,100 robots picking up items from crates and delivering them to packing stations, fulfilling thousands of grocery orders every week. They travel along a grid using an air traffic control system so they don’t collide with one another and travel up to 37 miles per day. They are said to pack 50 items in just five minutes, which amounts to 65,000 orders made by customers in a week.

“Such an operation would require huge volumes of data to be transmitted across a number of sensors to avoid real-time collisions. The speed and bandwidth of a 5G network would support robotic warehouses of this calibre,” Singtel said.

Robots can be controlled over wide distances using 5G technology

Last year, ABB and Ericsson, together with Swisscom, showcased how robots can be controlled over wide distances utilizing the real-time communication capabilities of 5G.

“With this technology the companies pave the way for the highest flexibility for machines on the factory floor. Utilizing 5G networks, the deployment and operations of large fleets of autonomous machines and robots will become a reality,” ABB said.

ABB also noted that a significant benefit from 5G in industrial environments is that instead of a single control/single purpose operating approach, multi-machines can be controlled by one central resource, reducing the cost of managing and maintaining OT as well as IT systems.

ABB and Ericsson have also teamed up and built within the EU project 5G-SMART a 5G testbed in the Ericsson smart factory in Kista, Sweden, to explore how 5G technology can enhance manufacturing use cases, with focus on robotics.

The main objective of the testbed is to investigate and validate use cases were software controlling the industrial robots can be moved from the robots themselves into an edge cloud platform and be connected to the robots via 5G wireless connectivity.

The following functionality will be investigated to be moved to the edge cloud:

-Simultaneous localization and mapping (SLAM) of the robots, based on sensor reading provided by the robots,

-Mobile robot localization, based on sensor readings and motion information from the mobile robot,

-Motion planning for the stationary and mobile robots.

According to Ericsson, smarter robots can carry out a greater number of tasks in the manufacturing process, allowing their human counterparts to be employed in other areas. “Perhaps most significantly, however, smarter robots enable increased industrial automation. Also known as ‘smart manufacturing’, the majority of production processes could be remotely controlled and monitored in the cloud, minimizing the need for plant infrastructure and dramatically reducing costs.”

For more 5G manufacturing content, check out the following:

- What is 5G manufacturing and what does it mean for productivity?

- Top 5 5G manufacturing use cases

- Three 5G manufacturing case studies: Audi, Haier, Bosch

- What’s the role of a digital twin in smart manufacturing?

- 5G manufacturing use case spotlight: Automated guided vehicles

- 5G manufacturing use case spotlight: Real-time video analytic

- How to improve Overall Equipment Effectiveness with 5G

- 5G manufacturing use case spotlight: Additive manufacturing

- What is lean manufacturing and how can 5G help?

- Top 5 5G manufacturing use cases

- What’s the role of AI in 5G manufacturing?

- What is a digital thread and what does it mean for manufacturers?

- What’s the role of edge computing in 5G manufacturing?

- 5G manufacturing use case spotlight: Industrial automation

- 5G manufacturing use case spotlight: Troubleshooting using a digital twin

- How can 5G enable industrial IoT manufacturing implementations?

- 5G manufacturing use case spotlight: AR remote assistance

- Do industrial IoT manufacturing implementations need 5G?

- 5G manufacturing use case spotlight: Supply chain optimization