Will 5G manufacturing power the Fourth Industrial Revolution?

The Fourth Industrial Revolution (4IR) will usher in smart factories. In these futuristic factories, connected devices will be able sense their environments and interoperate with each other, making decentralized decisions. Many expect this transformation will chiefly rely on the capabilities of next-generation 5G networks. The introduction of 5G manufacturing is a major priority for the telecoms sector, as well as attendant technology disciplines, and it has major implications for increasing productivity while controlling costs.

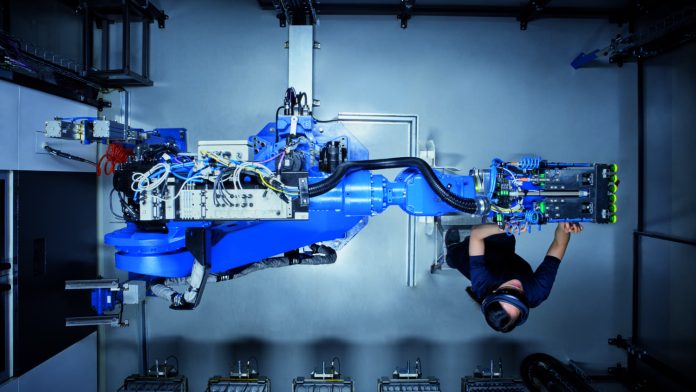

5G networks offer manufacturers the possibility to build smart factories and truly take advantage of technologies such as automation, artificial intelligence, augmented reality for troubleshooting, and the Internet of Things (IoT). The low latency, high reliability, and increased speed of 5G networks are essential to support emerging technologies and their novel applications in this field, such as process automation, remote monitoring, and collaborative robots, among others.

5G technology will also allow for higher flexibility, lower cost, and shorter lead times for factory floor production reconfiguration, layout changes, and alterations, which will result in significant improvements in terms of production.

How 5G manufacturing will enable predictive maintenance and reduce downtime

“As networks grow and become smarter, they will produce far more information than their predecessors. Manufacturers that can capture and crunch this information could produce actionable intelligence that increases productivity. 5G’s low latency and high-bandwidth capabilities can support this increasing data flow. Aside from increasing throughput, analyzed data can also help reduce downtime,” according to U.S. carrier AT&T. 5G-connected sensors can channel real-time information about equipment performance, ranging from vibration to noise data. Combined with machine learning algorithms, this data can help companies predict when expensive equipment is about to fail, reducing the likelihood of expensive downtime.

According to AT&T, 5G technology will enable manufacturers to drive more functionality closer to the edge of the network. “Because this network technology’s reliability is so high and its latency so low, equipment can communicate wirelessly with back-end systems for time-critical operations in ways that were not possible before. For the first time, this will combine fast production-line operations with the power of networked intelligence. We can expect new capabilities such as advanced visual recognition using the power of deep learning neural networks in the cloud. This will allow robotic systems to visually inspect products for quality control purposes in real time, with a high degree of accuracy.”

What implementation challenges face 5G manufacturing?

According to Telit, despite the improvements that 5G will bring to the manufacturing field, there are some big challenges associated with the implementation of this technology. The company noted that the biggest challenge for developers is that, for the first time, wireless technology will need to achieve virtually 100% reliability. Also, industry leaders are reluctant to invest in technology that’s different from what they are accustomed to and requires a new approach to networking infrastructure. “Given the excitement and rapid pace of innovation around 5G, these challenges are likely to be overcome in the next few years,” the company has said. “While 5G has yet to be fully realized in industrial and manufacturing settings, it’s set to play a fundamental role in how industrial sites work in the future.”

According to a report by PwC, 5G will be even more essential in the manufacturing space in a post-COVID-19 era due the unique advantages of 5G-enabled 4IR technologies in further automating the factory floor and incorporating new services into all kinds of products.

PwC also highlighted that most of manufacturers are already aware of the operational benefits that 5G could bring to their factory floors. However, concerns about the costs involved, the potential business value and the security of fully wireless systems will likely slow implementations for some time. However, these challenges should not prevent industry leaders from developing proof of concept for the operational value of 5G, and starting pilot programs to better understand the technical challenges involved, PwC said.

For more 5G manufacturing content, check out the following: