Danish shipping company A.P. Moller – Maersk (Maersk) has announced new smart logistics and warehouse facilities in China, Norway, and Pakistan. Each site puts focus on innovation and environmental sustainability. Maersk has also confirmed the acquisition of Danish project logistics specialist Martin Bencher Group for around $61 million.

Maersk’s stated goal is to decarbonise its entire operations by 2040. Maersk’s emissions targets entail that at least 90 percent of its global cold chain and contract logistics operations will be certified as green by 2030.

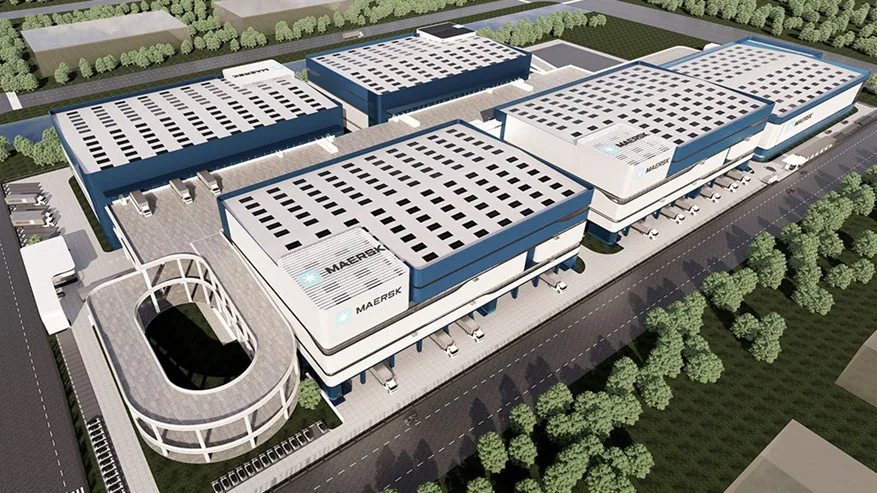

Maersk, which canned its blockchain-based TradeLens trading platform last November, said its new $174 million China warehouse, in the Lin-gang area of the Shanghai Free Trade Zone, will be a flagship venue when it opens in the third quarter of 2024. It called the facility its “first green and smart” flagship logistics centre in China.

The Lin-gang warehouse will cover a floor area of 113,000 square metres and a storage area of 150,000 square metres. It will comprise four ramped three-storey standard warehouses and one 24-metre-high warehouse with an automated storage and retrieval system (AS/RS). It will offer national and international fulfilment and distribution.

The company pointed to its proximity to Yangshan port and “favourable” free trade policies, and a strategy to provide “agile and sustainable” solutions, to “connect and simplify” customers’ supply chains. The facility will achieve “low or very low” greenhouse gas 9GHG) emissions, and apply for platinum level LEED (environmental design) certification.

The construction will use “environmentally-friendly” materials; the finished site will be equipped with rainwater management and solar power systems, plus LED lighting, nature ventilation, non-fossil energy heating systems, and electric vehicle and equipment charging piles, said Maersk.

The new facility in Norway, at Flatholmen quay in Aalesund, is for cold-storage, to serve the Norwegian seafood industry. It will be among the largest cold storage sites in the region, said Maresk, and will come into operation in the first quarter of 2024. It will be Maresk’s first low GHG emissions cold-storage site in the country.

It will offer 12,000 square metres of temperature-controlled space, and storage for over 33,000 pallets. It will achieve BREEAM certification for sustainable construction from the Building Research Establishment, said Maersk – “with zero direct emissions from operations” – and “true integrated” logistics conduit to reduce customers’ GHG footprints.

Aalesund, on the northwest coast of Norway, is the largest receiver of wild fish in Norway. It is home to the largest port in the region, handling around 16,000 vessels, and two million tonnes of cargo per year, including fish products, hydraulic machinery, ship building products, and furniture.

The third facility, at Port Qasim in Pakistan, measures 52,000 square metres, with six purpose-built sheds, and was opened last month. The new site makes Maersk the largest logistics and warehousing provider in Pakistan, it said, with a total footprint of around 120,000 square metres in seven cities.

Maersk claims the facility is equipped with “modern warehouse management systems” to deliver higher efficiencies, faster turnaround times, deeper visibility, and better control over cargo. “All of this will result in better predictability of supply chains,” it said.

It acknowledged the move was, in part, a strategic response to disruption from the Covid-19 pandemic, and to the warehouse value Maersk realised from being able to “store goods that were in lower demand” – prompting it to invest in the 26-acre site at Port Qasim for warehousing, consolidation, fulfilment centre, and cold storage.

It said: “Maersk’s end-to-end solutions ensured customers’ cargo kept moving. The warehousing facilities especially strengthened Maersk’s position by being able to store goods that were in lower demand and slowed down supply chains when needed. This garnered a lot of confidence… about Maersk’s resilience.”

Meanwhile, the $61 million acquisition of Danish project logistics specialist Martin Bencher Group will give Maersk additional capability with large cargo transportation. Founded in 1997, Martin Bencher Group has 31 offices in 23 countries, and around 170 staff. It focuses on oversized freight, including “everything from renewables to paper mills and power plants, as well as oil and gas projects”.

The TradeLens collapse last year will be completed by the end of the first quarter of 2023, with Maersk and co-parent IBM confirming that TradeLens offerings are being withdrawn and the platform discontinued. Maersk stated: “Maersk will continue its efforts to digitise the supply chain and increase industry innovation through other solutions.”

The TradeLens platform, announced in 2018, was jointly developed by IBM and GTD Solution, a division of Maersk, as a blockchain-enabled shipping solution designed to promote more efficient and secure global trade. Maersk called it a “bold vision” for supply chain digitization and a model for an “open and neutral industry platform”.

Rotem Hershko, head of business platforms at Maersk, commented: “Unfortunately, while we successfully developed a viable platform, the need for full global industry collaboration has not been achieved. As a result, TradeLens has not reached the level of commercial viability to continue work and meet financial expectations as an independent business.”