Australian outfit Konvoy Group started three years ago, in the summer of 2019, as a keg rental business, offering logistics support to craft brewers in its home country. It has, in the meantime, expanded its services portfolio, launched in international markets, and signed with global beer brands – through a period of pandemic, which has unsettled and refocused supply chains, and made its spinoff IoT tracking unit a crucial chaser for any cultured brew.

Indeed, the firm’s tracking solution – based on Sigfox at home and cellular abroad – has worked as a gateway device for the company’s entry into new international markets, as well as for its rapid expansion in Australia and New Zealand, where it expects to have 165,000 kegs under management by the end of the year and 250,000 by the time of its fourth anniversary, at the end of its next financial year in June.

As it stands, Konvoy is tracking 130,000 kegs in Australia and New Zealand. It has just opened a keg rental operation in the UK, with tracking included as standard, and will follow as a pure-play IoT provider in the US. These launches will be replicated, in mainland Europe and Asia, and also expanded – so the UK arm promptly opens a keg servicing unit, to clean and process kegs, like at home, and the US, in time, owns both a rental fleet and a service centre.

Marc Eggins, operations director at Konvoy Group, rewinds the narrative, and goes back to the start. “At heart, we are a keg rental business. We rent kegs on a pay-per-fill basis, mostly to independent brewers. So a brewery wants 50 kegs, say; we send them the kegs, and they fill them, and send them on to the venue – whether directly or via a warehouse or distributor. They are not responsible after they arrive at the pub or bar; we are responsible after that.

“Breweries like it because kegs are a problem. They get lost, and knocked about. In Australia, in particular, you have to recover them over long distances, which is expensive. Breweries don’t usually have the people to do that – so a sales rep ends up chasing kegs, as opposed to selling them. And there’s a cap-ex issue. A single keg is about £100; but for every keg you fill, you need three more: one in-market, one in the warehouse, and one in storage.

“And if you are losing five-to-10 percent, the losses quickly stack up. Brewers prefer to put money into marketing, sales, new tanks, growth – as opposed to an asset that just gets lost. So we’ve forged a strong business with the smaller brewers – which we have helped to grow. And from there, we’ve put together a strong value proposition for larger brewers – to buy and repurpose their kegs into our own fleets, to allow them to move into a rental model.”

The tracking logic is very plain, he explains. On average, Konvoy achieves a single extra fill per keg, per year – just by tracking and recovering it more efficiently. To put that in perspective: a craft brewer might manage three-and-a-half to four-and-a-half fills per year, he says (“in a market like Australia, moving kegs a long way”); a mega brewer, meanwhile, “like Heineken or Asahi”, will fill a beer keg 11-to-12 times per year (“in their smaller markets”).

“It is a 25 percent increase, potentially, on your usage per year,” says Eggins, starting with the straight efficiency-uplift for smaller brewers, and then extending it as a loose economy-of-scale sum for bigger ones. “If a brewer sells 100 kegs for £100 each, for example, and turns each keg once-more per year, then it is an extra £10,000 – for doing the same job. When you compound that to a brewer with a million kegs, then the gains increase fairly dramatically.”

ORIGIN STORY

But as above, the value proposition is not just about straight usage-to-cash efficiencies. He explains: “It also allows their service teams to service customers, instead of chasing kegs at the cost, potentially, of downtime in the brewery – which is that unknown expense for managing a keg fleet poorly.” It is the same flat-rate per-fill fee, he says, for both rentals and tracking data – bankrolled by Konvoy simply by “managing a smaller fleet for the same number of fills”.

Which distinguishes it from rivals in the straight rentals game, he explains; the tracking drives the efficiency, which pays for the tech in the first place, and brings the value in the end. The customer gets life data about the logistics of beer distribution – at no additional cost to brewers taking the rental service, and for a bundled IoT subscription fee for everyone else, as Konvoy is preparing for US customers. “Tracking is a unique selling proposition,” says Eggins.

He says: “For rental customers, it is all included – despite the cost of the device and connectivity. And we manage that just because we run a smaller fleet for the same number of fills – we lose fewer kegs and we fill them more. For customers with their own fleets, it provides data they never had before – which they can use in the same way we do, to circulate their kegs more efficiently, and get them back more quickly, and completely.”

What of the technology, then? Because Konvoy got its start with Sigfox – initially via Sigfox operator Thinxtra, offering decent Sigfox coverage in Australia and New Zealand, which put it onto Singapore-based Sigfox development house (and now Sigfox owner) Unabiz, which developed the original tracker, branded Katch, with the right form, function, and price. And yet Sigfox is a non-starter for tracking in certain geographies, such as the US, notably.

Eggins rewinds, again, to flesh-out the whole IoT origin story. “The thing is that without the [long-range wireless] tech, the best we could do with RFID was to get 70 percent of kegs scanned – which meant we never knew where 30 percent were. As brewers got bigger, and more parties became involved, scans got missed – because third-party logistics wanted to be paid for the scan, and all these other complexities that come from humans being involved.

“So we set out with Unabiz to build a tracking unit that could last the horrible life of a keg – being dropped and chilled, and filled with chemicals, and left for long periods in cellars without coverage. The initial plan was to do it just for the Konvoy rental kegs. But fast-forward 18 months, halfway through Covid, we had deployed 100,000 of these devices on our fleet, and started to receive enquiries from breweries, particularly in Europe, to white-label the solution.”

He goes on: “So from there, we shifted from this welder-on device for our own fleet – which was built in six months, and quite expensive actually, and not really commercially viable – to engage with Unabiz to reduce the size, make it easier to fit, and make it cheaper. So we went straight back to do the rebuild on it; and the new device can be retrofitted into the chime of a keg, at any location, and works commercially on a £100 asset.”

FULL SERVICE

The Sigfox question remains (and will be answered); so does a question about the precise makeup of the mark-II unit, to work in cellars and such (also to be addressed). But, briefly, to explain about the setup; the group comprises Konvoy Keg Rentals, handling the original rental service, via regional offices (Konvoy Australia, New Zealand, and UK, so far), and Konvoy Technology Group, managing the Katch tracking service, based on the Unabiz hardware.

The Sigfox question remains (and will be answered); so does a question about the precise makeup of the mark-II unit, to work in cellars and such (also to be addressed). But, briefly, to explain about the setup; the group comprises Konvoy Keg Rentals, handling the original rental service, via regional offices (Konvoy Australia, New Zealand, and UK, so far), and Konvoy Technology Group, managing the Katch tracking service, based on the Unabiz hardware.

But Konvoy Group also includes this third service proposition, branded as Konvoy Services, and established via the purchase of Australia-based Keg Services in 2020 – because “kegs get beaten around, and need their necks and chimes straightened”. It is “the only keg servicing facility in Australia and New Zealand”, he says. Konvoy’s UK entry, for rentals and tracking, will be attended, presently, by its first Konvoy Services outpost, as well, he says.

He explains: “We want that full service piece. If you don’t want to own kegs, we want you to rent them from us, and also provide tracking and servicing, as well. If you want to own your own kegs, we want to help you track and service them.” In most cases, as discussed, and as with the pending US launch, the IoT tracking works as the gateway service for the company’s geographic expansion; invariably followed by keg rentals, and then keg servicing.

But such a brewery crawl in the US, and even into much of Europe, hinges also on IoT connectivity technology. In July, Konvoy bought Lisbon-based firm Onalytics for an undisclosed fee. “Onalytics was doing the same as us, but with LTE-M and NB-IoT,” explains Eggins. “We did that purely to prepare for the US market.” Konvoy noted high demand at the Craft Brewers Conference in Minneapolis, in May. “Demand is definitely there,” he says.

The firm is already running trials in the US and Canada, with 20,000 “production devices” slated for deployment in February. He says: “We didn’t see another option when we started. Sigfox was the only device to hit a price point, battery life, and coverage footprint that we could use on a keg. But there is just no way the network is going to be there to allow us to have a North American device ready. And it isn’t available in parts of Europe, or Asia, either.”

What has the response been from Unabiz, as Konvoy’s primary OEM supplier – and as the new owner of Sigfox, also proclaiming a transcendary role as a universal IoT development house? Does the Unabiz story – about a brave new world of ‘unified LPWAN’ supply – hold up? Sort of, says Eggins; more so in theory than in practice. The relationship is close, he says, but Onalytics was better with cellular at the time, when the US plan was formalised.

“We already engaged with Unabiz prior to the Onalytics deal, to look at what it could do with cellular. But at that point, Unabiz wasn’t ready to build a device at the price we needed. The guys in Portugal were the only ones to have cracked it. But we have been transparent with them, all through – that we need a secondary solution. Because there are 15 million kegs floating around the US, and it would be silly not to chase a five or 10 percent cut of that,” he says.

IOT MECHANICS

Right; so to this other question: what about the mechanics of the solution, which Unabiz was so successful with in the first instance. What is actually in there? How does it work? At what points are you tracking the keg, on a low-power wide-area (LPWA) network? Is Konvoy tracking temperature, and movement (knocks and jolts)? Is it tracking fill levels? Because presumably the network cuts out in a beer cellar, and Wi-Fi just reintroduces manual intervention?

“Yes, so we don’t worry about fill levels, just because the sensors aren’t that accurate, and they are too expensive, anyway; and then also, like you say, because you are generally not going to get a message out from a cellar,” says Eggins. He confirms as well that Wi-Fi is a non-starter, and that tracking effectively stops when the pub takes possession of the keg. In sleep-mode, the unit attempts to make a connection every 24 hours, until it succeeds.

The unit features a temperature sensor and an accelerometer, alongside the Sigfox transceiver – or the cellular IoT module in the upcoming US model. The accelerometer records tilt movement, based on “how kegs are moved on and off trucks, and into storage”, which generates a trigger event in the firmware, which issues a message on the network with attendant location and temperature data.

“One of the benefits with Sigfox is we can get messages out extremely quickly, at extremely low power – before a keg comes off a truck and goes into a cellar. That is where Sigfox works well, and where it is important – if a brewery is paying for end-to-end cold-chain, and a keg arrives at a warehouse at plus-five degrees, or if a venue says the beer doesn’t taste right. Then we can track the temperature variation, with the location data attached.

“We’ve had that happen; one of our local distributors had a call from a venue saying the beer was terrible, and the brewery asked us, and the data showed the keg had been sitting in the sun outside the pub for five hours, and the device had got to 50 degrees. While we are not using the data to place blame, it gives customers a safety net on the way through,” says Eggins.

Not to dwell; but are there differences between the established Sigfox solution and the newer cellular version – in terms of performance, hardware costs, connectivity costs, and power usage? He responds: “Costs are essentially the same [for airtime]. It changes market to market on cellular. In some markets, cellular is cheaper than Sigfox, and in others it is more expensive. But it is a per-device subscription with both, based on the amount of data per month.

“[In terms of performance] we get a lot more data per message with cellular, but we can’t get as many messages for the same battery life. So we have to be more careful about when we message with cellular, to ensure we don’t decrease the battery too far. So the cellar situation (daily messages in long storage), for example, is covered off a lot more easily with Sigfox than the cellular – just because we can push more messages from there.”

MASSIVE SCALE

Its forthcoming US adventure might be a cellular affair, but the new UK operation, already live, is another Sigfox venture for Konvoy, starting with tracked keg rentals, and expanding to keg services, at some point, according to the plan. He restates: “The first step is tracking, which is easier just because it requires very little infrastructure; the second step is rentals, and the third step, very much dependent on volume, is the service solution.”

Konvoy also has “a couple” of cellular IoT trial deployments in mainland Europe, through Onalytics in Portugal, to go with a couple of other continental Sigfox brewers developed under its own steam. “We have five different keg owners using the tracking solution in different countries in Europe at the moment.” In total, all over, it claims 12 customers are testing its tracking solution, with another seven set to start trials next month (December).

But the biggest problem, with the Australia-side extension, the UK rollout, and US experiment, is getting hold of hardware. Eggins comments: “We have more devices arriving in December. But we can order kegs quicker than we can get devices on them, so we are running at a deficit at the moment. The expectation is to be tracking 250,000 by June, but that depends on devices coming in time. That is the question; the supply chain is still up and down.”

There are a couple of “larger” breweries among the new trialists, which could “really move the dial” for Konvoy, says Eggins. “They are keen to keep it under wraps until we get through the trial,” he adds. It is an interesting dynamic for Konvoy, between its original market of local craft brewers, looking to outsource keg supplies, and a potential market of multinational brands, which might just deliver the kind of ‘massive’ scale that IoT likes to talk about.

“Yeah, and we want to work with all of them. We’ve seen brewers start from nothing, 50 kegs a month, now taking 5,000 a month. That growth is the most enjoyable part. But we are also sitting in an IoT business where scale is everything – and that scale will come from the ones with a million kegs. But what our software provides to a 50-keg brewer is very different, and customised, compared to what it provides a million-keg owner – but it has value to both.”

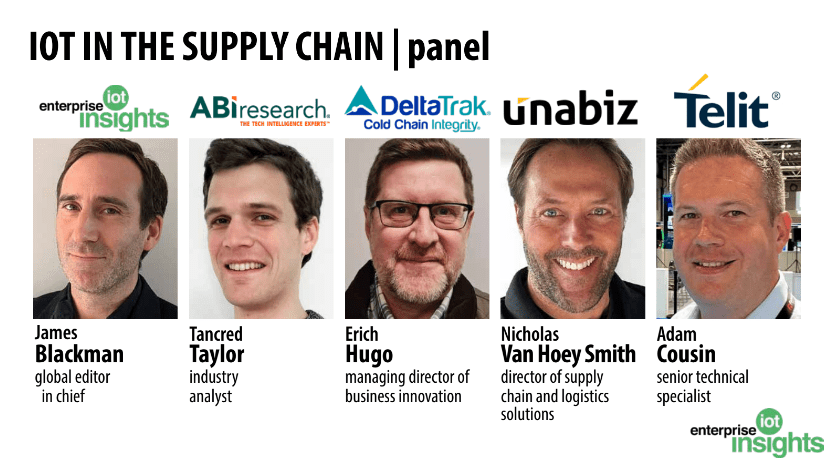

For more on IoT tracking in the supply chain, join the editorial webinar (on-demand) on: IoT in the Supply Chain and Logistics Industry – how IoT grew up and got real, in the hardest industry of them all. The session features a crack no-holds-barred speaker lineup, with panellists from ABI Researchm, DeltaTrak, Telit, and UnaBiz Group. Sign up here, or by clicking on the images below.