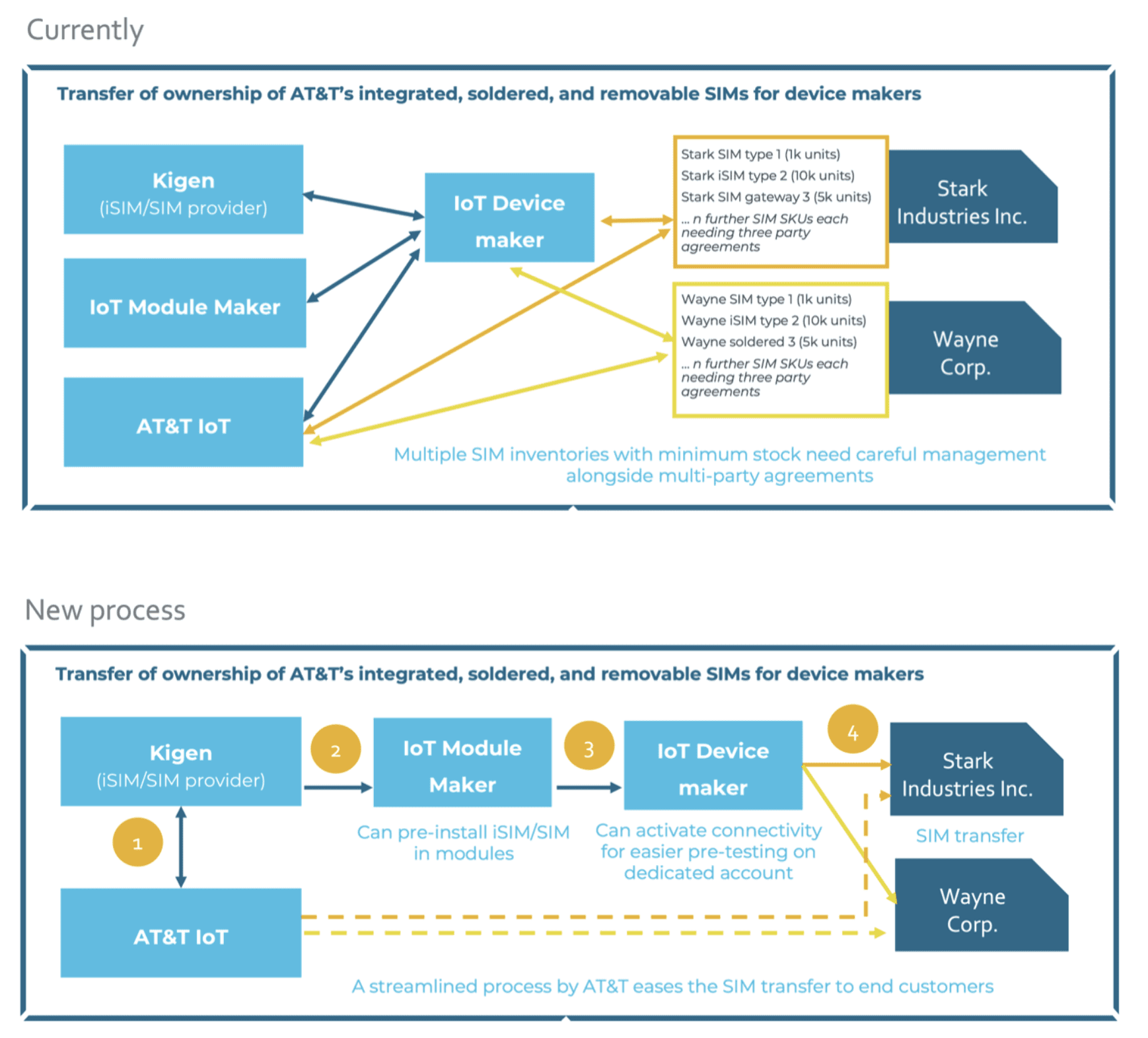

Belfast-based SIM development firm Kigen, previously part of chip design company Arm, is working with US carrier AT&T to enable IoT manufacturers to transfer SIM ownership of AT&T-connected IoT devices to their customers, in the form of end-user facing IoT providers, post-production – without having to hold stock of AT&T SIMs for each customer, in each market, in order to navigate fast-paced multi-party production schedules. The idea is to shorten the supply chain and streamline the manufacturing process.

Kigen has been working with AT&T on the project for 12 months. AT&T is using Kigen’s SIM operating system, data generation, and key management services to offer standard SIM, embedded SIM (eSIM), and integrated SIM (iSIM) options to IoT developers and manufacturers to connect to its network – enabling the latter to cover for connectivity at either the point of device production, module supply, or chipset supply, respectively.

The new process, already adopted by module manufacturers “such as” Japan-based Murata, provides a facility for device makers to transfer ownership of AT&T SIMs, of whichever types, to their customers in the cloud – in AT&T’s co-called Control Center, specifically. It simplifies inventory management, particularly for IoT manufacturing companies with large numbers of customers, said Kigen.

In most cases, device manufacturers have been required, effectively, to purchase multiple stock-keeping units (SKUs) for each end-customer or end-market, with unique SIM identifiers to specify the carrier’s SIM profile and the customer’s own “details”. This has bloated their SIM inventory and “complicated global product rollouts”, said Kigen. Its system means the manufacturer can keep a “general inventory” of AT&T-approved any-SIM IoT modules, instead.

The manufacturing company can “bind” these modules to the customer account “at the time of transfer, ready for activation”, said Kigen. “SIMs can be aggregated by device makers during the manufacturing and assembly, eliminating the need to keep a stock of AT&T SIMs per customer.” The service works for AT&T’s main cellular IoT connectivity portfolio, covering LTE, LTE-M, and NB-IoT.

Kigen said in a statement: “Variations in sourcing the right form factor, profile, and stock can be the cumbersome first step for businesses that are driving product innovation with new cellular technologies. Currently, the burden of working on multiple-party agreements can take weeks during the crucial stages of deployments for end-user enterprises.”

It said elsewhere: “Access to a new cache of SIMs that are compatible with cellular chipsets and secure IC vendors offers additional flexibility that results in supply chain optimization. This streamlined approach also simplifies the manufacturing process by allowing suppliers, original equipment makers, and licensees to identify the ideal SIM solution earlier in the design process, meaning device estates can scale sooner upon deployment.”