Siemens Energy will utilize the Nvidia Omniverse platform to create digital twins tasked with supporting predictive maintenance of its power plants.

“Nvidia’s open platforms along with physics-infused neural networks bring great value to Siemens Energy,” said Stefan Lichtenberger, technical portfolio manager at Siemens Energy. “Nvidia’s work as the pioneer in accelerated computing, AI software platforms and simulation offer the scale and flexibility needed for industrial digital twins at Siemen Energy.”

In a blog post, Richard Kerris, Nvidia’s industry general manager for media and entertainment, further described the value that the Omniverse can bring to Siemens Energy’s operations, writing that the chip company has been enlisted by Siemens Energy “to develop a new workflow to reduce the frequency of planned shutdowns while maintaining safety.”

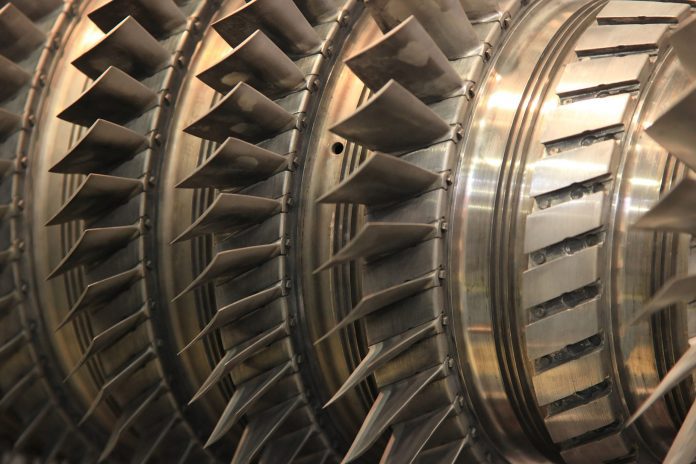

Recovery steam generators (HRSGs) at the Siemens Energy plant use exhaust heat from large gas turbines to create steam used to drive the steam turbine, a process that improves the thermodynamic efficiency of the power plant by more than 60%, according to the utility company.

“Real-time data — water inlet temperature, pressure, pH, gas turbine power and temperature — is preprocessed to compute pressure, temperature and velocity of both water and steam,” Kerris wrote. “The pressure, temperature and velocity are fed into a physics-ML model created with the Nvidia Modulus framework to simulate precisely how steam and water flow through the pipes in real time.”

Because a steam and water mixture can cause corrosion at some points on the steam generators, maintenance and repairs can lead to significant revenue and time setbacks for Siemens Energy.

The companies hope that by implementing a real-time, physics-based simulation of the water and steam in HRSG digital twins will help Siemens Energy predict corrosion and mitigate downtime in the real world by reducing the frequency of necessary corrosion checks.

“Siemens Energy estimates that a 10% reduction in the industry’s average planned downtime of 5.5 days for HRSGs — required among others to check wall loss thickness of pipes due to corrosion — would save $1.7 billion a year,” claimed Kerris.

Telecom equipment provider Ericsson is also making use of the Omniverse platform, announcing last week that it is working with Nvidia to build virtual versions of real cities. The platform is helping Ericsson establish optimal real-world 5G antenna placement. Additionally, the BMW Group began using the platform earlier this year for virtual planning and engineering in highly complex manufacturing systems.