Red Hat and Intel have extended their Industry 4.0 partnership to combine their open source software and industrial edge hardware to spur the smart manufacturing and smart energy sectors. The pair are looking to sell integrated hardware and software to provide the ‘smarts’ in industrial control system (ICS) solutions, in order to drive a new wave of industrial automation.

They will also look to drive innovation in other Industry 4.0 areas, such as private wireless networks, open manufacturing platforms, energy data platforms, power sector digitalization, and autonomous mobile robotics, they said. But their initial focus is on selling integrated hardware and software tools to ICS vendors to deliver IT/OT solutions that cover shop-floor control and intelligence, through to “full IT manageability”.

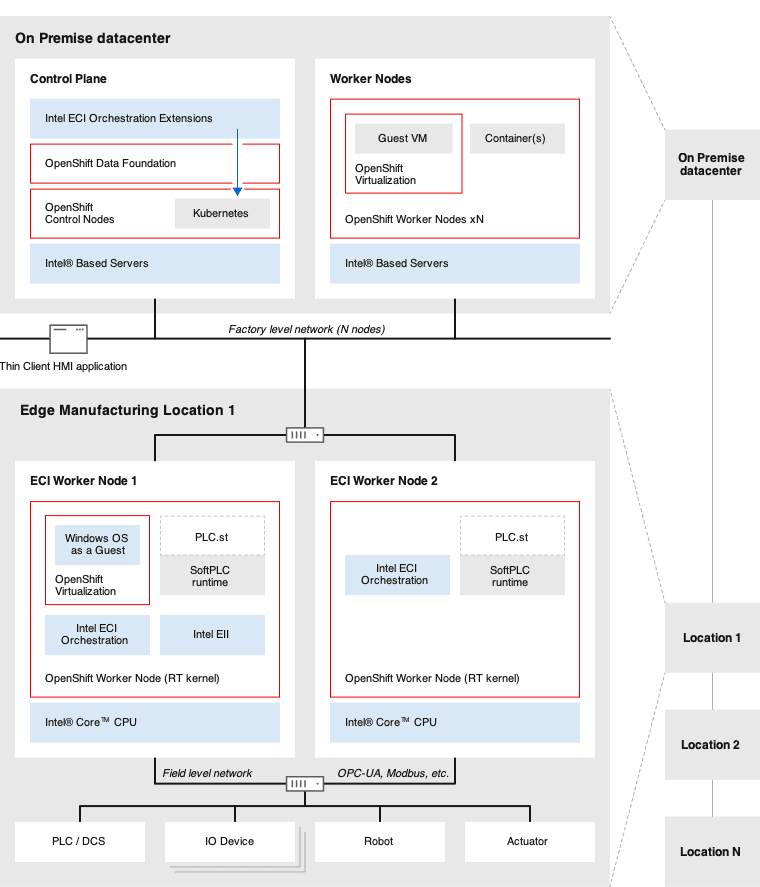

Their combined componentry comprises Intel’s industrial edge controls (Intel ECI) and insights (Intel EII) packages with Red Hat’s open hybrid cloud tech. They want to “help to build the foundation of the modern factory edge”, they said, by introducing industrial firms to software-defined ICS solutions. Intel has developed a software reference architecture, based on its ECI solution, for “open and portable” ICS platforms.

Red Hat, meanwhile, is committed to helping ICS vendors integrate Intel’s ECI controls into their solutions. The pair said their open-source ICS tools will drive automation and intelligence at the edge, and allow for AI/ML models to be updated on the fly “without impacting the reliability or resilience” of enterprises. The illustration below (see bottom) shows an Intel ECI deployment on top of Red Hat OpenShift in multiple locations, designed for closed loop control applications.

A statement said: “Industry 4.0 is picking up speed across the manufacturing and automotive sectors. Implementing Industry 4.0 technologies and processes can lower costs, increase efficiency, and reveal advantages by capturing, analyzing and acting faster and more effectively. With more compute power at the edge, businesses can connect the unconnected, converge and virtualize key workloads, and integrate the latest IoT in manufacturing use cases.”

Christine Boles, vice president of Intel’s IoT group and general manager of its industrial solutions division, said: “Our collaboration is creating new opportunities to advance Industry 4.0. Red Hat’s expertise in cloud-to-edge application platform delivery and Intel’s strength in compute platforms from edge to cloud, including industrial hardware and software, will give customers the flexibility of an IT platform and the resilience demanded in an OT world.”

Besides, the pair listed joint work on: private 5G networks, including with telco and industrial partners to create optimized, scalable, and secure solutions based on Red Hat OpenShift and Intel’s Xeon product line; edge processing in small-form IoT devices, combining OpenShift platforms and Intel NUC products; and autonomous mobile robots (AMR), using OpenShift and Intel’s edge insights for AMR (EI for AMR) software development kit.

They also referenced their work as members of the Open Manufacturing Platform (OMP) to support “platform-agnostic data-centric solutions based on open standards”. In the energy sector, they are developing an Energy Data Platform for closed-loop automation between power operators and various service providers, and on power sector digitization to bring software-defined control and intelligence to substations.