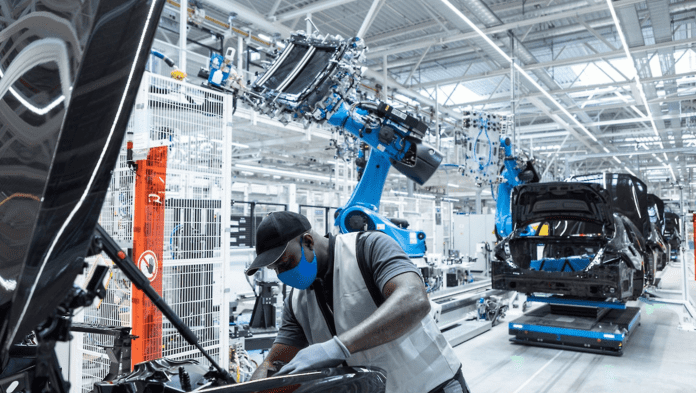

Mercedes-Benz (Daimler) has opened the doors of its new 5G-connected €730 million Factory 56 facility, part of a €2.1 billion “future-oriented” car plant and the administrative area in Sindelfingen, in Germany. The highly-digitised Factory 56 facility, networked by Telefónica Germany and Ericsson, is billed as the Industry 4.0 template for all of the company’s global production sites.

The structure, near Stuttgart in Baden-Württemberg, sets “new standards for the automotive industry”, the company has claimed, including zero-carbon production, and a 25 percent jump in efficiency compared with the old S-Class assembly line at the site. Mercedes-Benz can switch production in days between any model in either its conventional, hybrid, and electric lines.

Two-and-a-half years in construction, Factory 56 covers 220,000 square metres. The work with Telefónica and Ericsson, which started last summer, was presented at the time as “the world’s first 5G mobile network for automobile production”. Mercedes-Benz is managing the 5G infrastructure itself.

The company stated: “[The] high-performance WLAN and 5G network provides an important basis for full digitisation. It uses ultra-modern Industry 4.0 applications – from smart devices right up to big-data algorithms. Digital production technologies have been implemented everywhere.”

The construction used 66,300 cubic metres of recycled concrete, along with 6,400 tons of steel (about as much as was used in the Eiffel Tower, the company said). The facility hosts hosts a photovoltaic system, comprising 12,000 photovoltaic modules with a 5,000 KWp (kilowatts peak) output, and a DC power grid and energy storage based on reused vehicle batteries, with a capacity of 1,400 kWh.

But the new private 5G network, along with the chain of IoT sensors and analytics-based AI technologies, as well as the company’s MO360 ‘digital ecosystem’, establish the site’s flexibility. More than 400 automated guided vehicles (AGVs) are in operation at the plant, connected by 5G.

The MO360 system comprises a family of software applications connected via shared interfaces and standardised user interfaces. MO360 integrates production and IT data with 30-odd other car plants worldwide. Elements of MO360 are in use at these other 30 plants, too.

Two so-called TecLines serve to avoid fixed points in the assembly process, improving the flexibility of the entire factory, said Mercedes-Benz. “They bring together all the complex plant technologies at one point. This means that conversion work necessitated by the integration of new models, for example, is easier to carry out in the other areas of the assembly hall,” it said.

Modular production stations have been established, for connecting vehicle bodies to drive systems, to avoid disruption when switching between production jobs. Augmented and virtual reality (AR and VR) has been used throughout construction, running on the 5G network, and is being utilised in production processes, as well.

The factory is paperless, saving 10 tonnes of paper per year. Each vehicle is digitally tracked on the line via a positioning system. Relevant vehicle data is displayed to assembly staff in real time. Digital tracking and tracing of goods in and out of the factory is also in place, said Mercedes-Benz, along with material flows around the world.

“The concept of Factory 56 will be gradually transferred to all Mercedes-Benz car plants around the world as a blueprint,” the company said.

Ola Källenius, chairman of the board at Daimler and Mercedes-Benz, said: “Factory 56 sets the direction for the future of automobile production at Mercedes-Benz: resource-friendly, connected and flexible. Because we consider the transformation of our industry to be a holistic task that includes products as well as the entire value chain.”