The rail transport division of Japanese industrial conglomerate Hitachi Group has announced a deal to acquire UK-based rail technology firm Perpetuum for an undisclosed fee.

Perpetuum, based in Southampton, offers train monitoring solutions that combine IoT-based wireless sensors and AI-based data analytics to enable train companies to identify and fix faults before they disrupt rail traffic. It claims “blue-chip customers across three continents”, including a number of UK train operating companies. None of the 3,000 carriages fitted with its sensors have so far had critical components fail in service, it says.

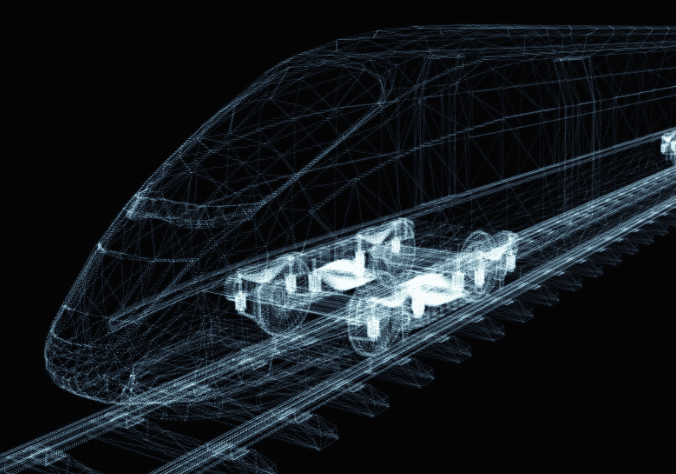

Perpetuum’s “self-powering” digital sensors detect on-board vibrations and send back real-time data about the performance of critical train parts – including wheel sets, gearboxes, motors, and ‘bogies’ (the wheeled trucks that ride the tracks and support the train) – faster and more accurately than traditional condition-monitoring approaches.

Hitachi said it will fit Perpetuum sensors to the “hundreds of trains” already serviced around the world by the wider mobility business. It said combining with AI-led analytical tools in Hitachi’s cloud-based Lumada IoT and AI platform will help faults to be fixed before they impact services, parts to be replaced when they need to be, and maintenance costs to be reduced.

It said integration with Lumada will see Perpetuum’s products also “go beyond wheelsets and bogies to provide actionable information wherever it is generated on the train,” said Hitachi.

Hitachi Rail provides rail solutions across rolling stock, signalling, service and maintenance, and digital technology. It operates in 38 countries, and employs 12,000 staff. In line with the broader industrial-change agenda of its parent business, its stated vision is to use IoT and AI to improve reliability of train services, including the 276 Hitachi-built trains on the UK rail network.

It claims to be uniquely positioned to offer “full service solutions for passenger and freight operators, globally, from driverless metros, to high-speed bullet trains and signalling solutions”. It said service and maintenance is key to its offering, and the new business unit will complement solutions already in place for customers.

The deal represents further direct investment by Hitachi into the UK, following its £100 million investment in a train manufacturing plant at Newton Aycliffe in County Durham, including a new £8.5 million welding and painting facility. Hitachi Rail recently won a £400 million contract with East Midlands Railway for a fleet of new intercity trains, which will debut in 2022.

Andrew Barr, group chief executive at Hitachi Rail said: “The inclusion of one of the most exciting, pioneering companies in digital asset management is an exciting development for our global mobility business. Perpetuum’s data-driven insights will offer further improvements to the service we provide to our customers – leading to better journeys for passengers.

“It also supports Hitachi’s growth in the digital technologies space, which is becoming increasingly key to our offering – adding value to support our global customer base. Being part of Hitachi will present vital opportunities that only a global transport giant can offer.”

Steve Turley, chief executive at Perpetuum, said: “Being part of Hitachi will present vital opportunities that only a global transport giant can offer. We look forward to better supporting our existing and new customers in the future.”

Last month, Perpetuum was awarded a contract by Innovate UK to deliver train-axle crack monitoring (TAMON) for onto a fleet of class 802 trains for Great Western Railway. It nominated Hitachi Rail as its partner in the project, which seeks a more efficient data-led model for identifying crack failures in train axles.

The TAMON project is utilising a new version of Perpetuum’s wireless monitoring system to deliver all the previous monitoring features for wheel, bearing and track monitoring, as well as for axle shafts. It is expected to bring benefits including reduced maintenance and inspection costs, real-time decision making, reduced downtime for rolling stock, and enhanced safety.