Bosch has raised more than €1.5 billion in revenue from the implementation of Industry 4.0 techniques in its own factories, as well as its customers’ factories, during the past four years, it has said. The company has set an incremental revenue target of €1 billion per annum by 2022 from applying digital-change solutions inside and outside of its own factories.

“Industry 4.0 pays off. Digital and connected solutions are making factories more efficient, more flexible, and more productive,“ commented Rolf Najok, board member at Bosch, ahead of the German group’s assault on Hannover Messe 2019, the annual Industry 4.0 shindig in Germany, next week.

Bosch started connecting its manufacturing and logistics operations as far back as 2012, it said. Its Bosch’s industrial technology business sector is seeing decent growth, with preliminary figures for 2018 sales showing sales of €7.4 billion – up 8.9 per cent, and 11 per cent as an adjusted figure.

Bosch’s plant at Blaichach in southern Germany introduced modern manufacturing technologies that increased production volumes for antilock braking system (ABS) and electronic stability program (ESP) units by 200 per cent over six years, without expanding its facilities or making acquisitions.

The company has flowed its digital technologies through its supply chains. “If you take the idea of the factory of the future to its logical conclusion, distinctions break down and you see that manufacturing and logistics have to be thought of as one element. This is the only way for Industry 4.0 to succeed in practice,” said Najork.

It said advanced LTE and incoming 5G technologies are at the heart of its automation efforts. “5G transmits data up to 100 times faster than the previous standard. Reliability has increased while data transmission delays have fallen to a minimum,” the company said in a statement.

“5G will be the central nervous system in the factory of the future,” said Andreas Müller, a Bosch researcher and chairman of the 5G Alliance for Connected Industries and Automation (5G-ACIA).

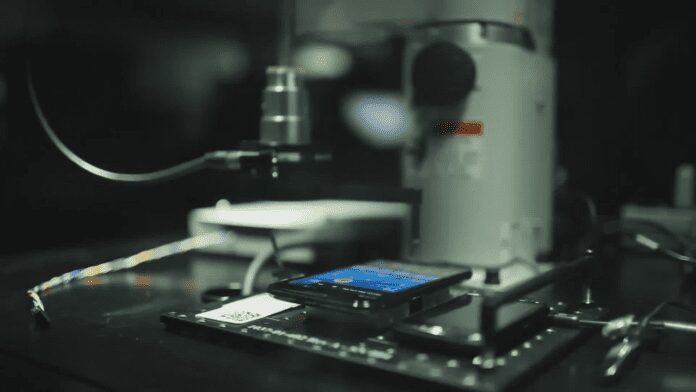

Bosch will test 5G at its own plants before the end of the year, it said. In Hanover, it is combining with Nokia and Qualcomm, among others, to bring 5G connectivity to a 3D printer for the first time. “This will make it possible to take some of the control elements that would normally be integrated into the machine and outsource them to a local manufacturing cloud,” it said.

Machines with this feature are leaner, cheaper, and easier to maintain, it said.

Meanwhile, the German outfit is also oushing artificial intelligence (AI) – on the show floor, and in-house and out-of-house going forward. Najork commented: “Bosch regards AI as a key technology. Our goal is for all Bosch products to be equipped with AI, or for AI to have played a part in their development and manufacture, by the middle of the next decade.

In Hanover, Bosch Rexroth, the group’s automation technology division, is showing a laser-equipped autonomous transport vehicle for carrying materials from warehouses to production lines. The shuttle creates its own map of a site, and updates it continuously to avoid collissions. It is also showing an autonomated loading platform to go with it.

Bosch has pooled software and services under its Nexeed brand, part of its new ‘connected industry’ business unit. Freight on its factory shuttles has been tagged with a Nexeed-branded track-and-trace applications to transmit data about its location, temperature, and vibrations.

Bosch will also present an AI-based system for visual quality control. Called ViPAS, it combines a gripper arm, camera, and analytics software. The technology is being piloted at a plant in Nuremberg, sorting parts as either ‘ok’ or ‘not ok’, it said. It will be rolled out in due course.