Solar equipment manufacturer SunPower took a five-step process to turn a Latin American facility into a smart factory

In a paper published by MESA International, a nonprofit association for manufacturing enterprises, SunPower Manufacturing Project Manager Nikhil Padhi provides an experience-based guide to how the company re-invented operations at a Latin American facility to use technology to create a smart factory.

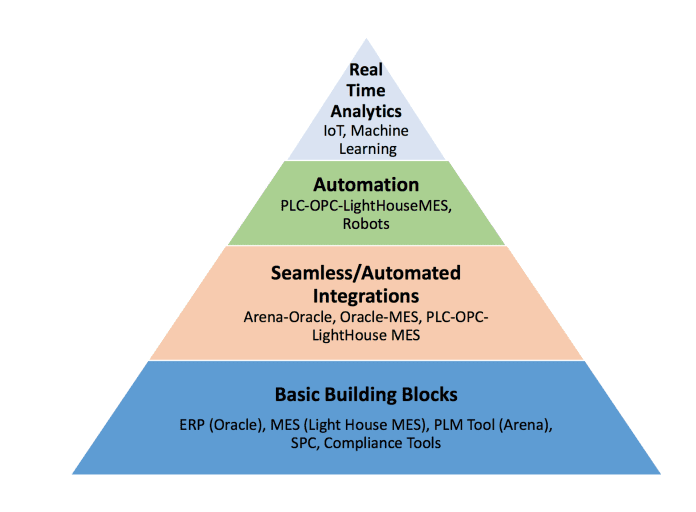

Padhi described three key challenges–cost reduction, the “need for strong traceability,” and regular launch of new products. In the paper, he outlines a five-phase approach:

- Phase 1–Working with various vendors, bills of materials and stock keeping units information was moved into a single-node serve architecture. Core and edge switches comprised the network architecture and a firewall provided security.

- Phase 2–The Oracle electronic business suite (EBS) was integrated with the Lighthouse manufacturing execution system (MES) to reduce manual processes and increase productivity. Because the data store was becoming increasingly “mission critical,” redundancy and load balancing were added to the server and storage configuration.

- Phase 3–Machines were equipped with sensors to capture data based on an industry-standard programmed logic control (PLC). “We introduced conveyer system for most part of the factory lay out. We built integration between PLC and MES…so that most of the transactions were logged automatically.”

- Phase 4–In this step, robots were introduced to in an effort to improve cost per watt of electricity used and decrease the number of defects. Robotics vendors had VPN access to floor machines to facilitate remote troubleshooting and maintenance.

- Phase 5–Real-time analytics were leveraged to conduct predictive maintenance, “improve energy management, reduce defect, etc…We adopted a phased approach where we started off with one use case and gradually going to address remaining.”

The results included a 10% reduction in cost, 40% reduction in direct labor and 40% improvement in throughput.