GE Digital, which specializes in software for industrial internet of things (IIoT) use cases like smart manufacturing, is adding a new service to its digital transformation offerings, this one with a focus on helping customers achieve return on investment more quickly. Dubbed Acceleration Plans, the service set includes “critical product support, end-user training and education, data health and overall organizational adoption needs,” according company literature.

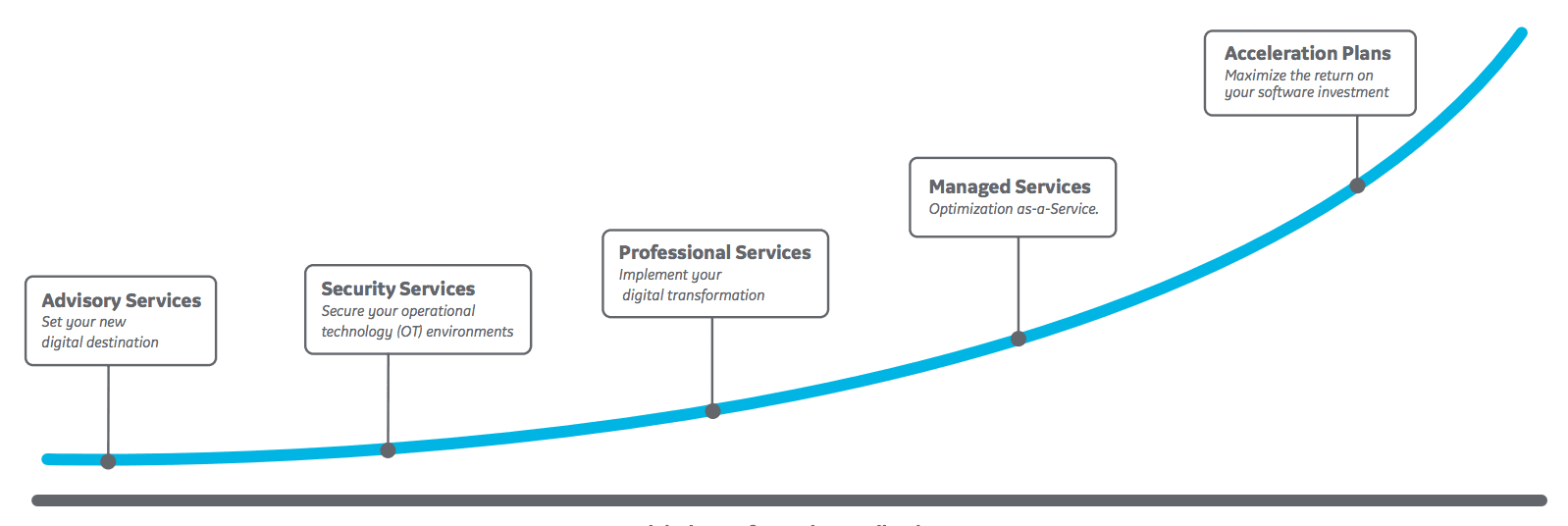

In terms of the overall digital transformation process, GE Digital breaks it down into a five-step process that corresponds with its portfolio:

- Advisory services to identify needs and goals;

- Security services, a focal point in IIoT project consideration;

- Professional services related to project implementation;

- Managed services–“optimization as a service;”

- Acceleration Plans to “maximize the return on your software investment.”

GE Digital SVP and Chief Customer Success Officer Chad Naeger said, regarding Acceleration Plans, “Only 15% of software deployments are considered very successful. Organization readiness, support, training and data quality need to be accounted for if positive business outcomes are going to generated.” He pointed to the company’s internal focus on embracing new technologies, noting, “Customers…want a partner who has deep industrial domain experience, offers innovative software and analytics solutions, and most importantly, who has also gone through a digital transformation and realized the benefits.”

In addition to its Predix cloud platform and managed services, GE Digital address smart manufacturing directly with its Brilliant Factory software, which company VP of Manufacturing Industries discussed earlier this year at the Enterprise IoT Summit in Austin, Texas. The tool allows companies to link design, engineering, manufacturing, supply chain, distribution and services into one platform–it “connects resources including people, machines and materials,” Boris said. “The software create a detailed, real-time, historical record to analyze variability.”